Gallery

Precision Calibrations believes in giving back to the community. Last year, we supported the local Mountain Bike community by sponsoring the 2019 Shoreline Shred mountain bike race. It was fun to volunteer at the event along with purchasing all of the events T-Shirts for the volunteers and for reselling. We hope to be a part of next year’s event. If you have not checked out the trails in Claremore, you need to get out and hike or ride the many miles of trails now available to the Claremore community. Enjoy the trails, be safe and remember to tell your friends about the trails.

Precision Calibrations was started in 2009 during the big stock market crash. Founder and owner, Nathan Saylor a 10-year Navy veteran started the business in his garage with only a calibrator and paperless chart recorder. Here is a picture of our new on-site trailer. Now it is possible to do more calibrations for our customers at the customer site. The mobile lab enables several technicians in a controlled environment to perform calibrations of smaller hand tools like calipers, micrometers, torque wrenches and pressure related items like pressure gages and transducers. We are also able to do a variety of handheld electronic multimeters and other electronic meters.

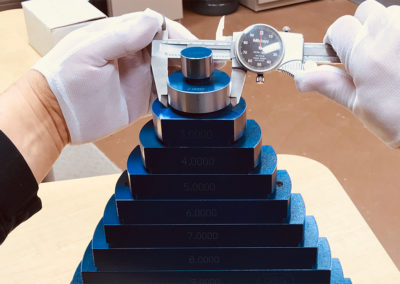

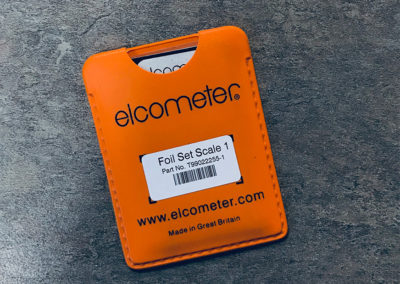

Some of the handheld measurement tools that Precision Calibrations will calibrate might be like this caliper shown in the picture. Many of our customers are manufacturers of airplane parts and so they are required to have their hand tools periodically checked or calibrated. To ensure proper operation and correct measurements by the user, our technician will perform a list of checks to ensure the caliper is operating properly and measuring correctly. Once the caliper is checked by using a certified measurement standard, a sticker is applied to the instrument and a certificate of calibration is generated and provided to the customer for their records.

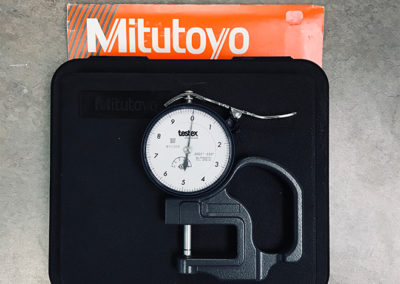

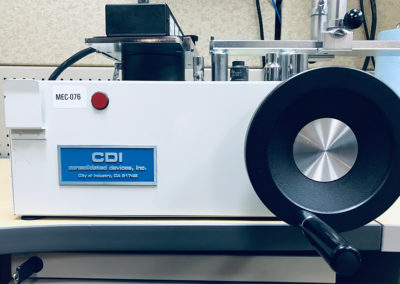

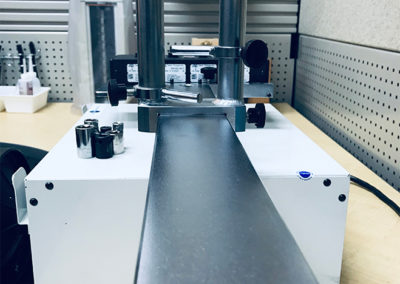

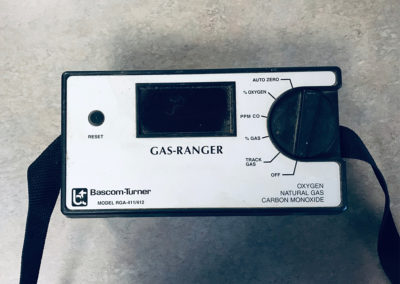

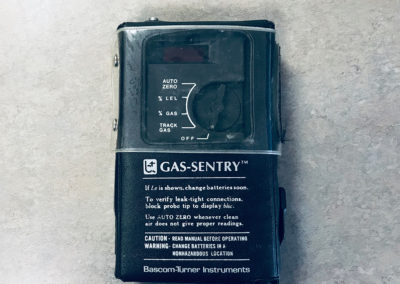

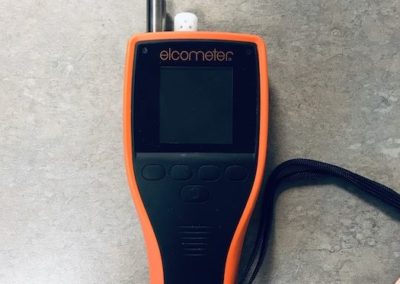

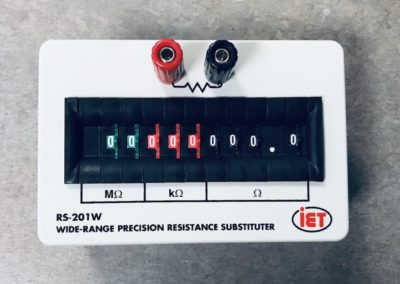

Precision Calibrations will perform calibration services for a wide assortment of testing and measurement equipment. Whether you have the newest type of measurement equipment or you still have some of that older well-built stuff, Precision Calibrations can probably still test it for proper operation. One thing about the team at Precision Calibrations is that we are not afraid to tackle even the more difficult tasks. One way or the other we will get the job done for you. If we cannot do the work in our lab, we have an approved accredited vendor list that we can call upon for assistance.

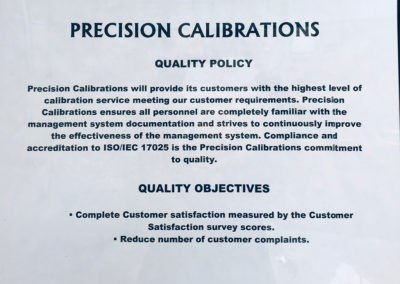

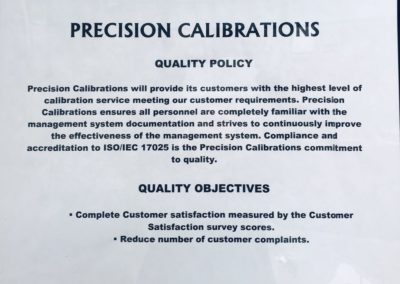

It is not easy to meet all the requirements of today’s many specifications. Each person of a calibration team must take on the responsibility to not only perform their job efficiently and correctly, but they must continually look for ways to improve on the process. Each member of the calibration team must always be thinking about quality work for the customers. We receive many online reviews that say how much it is appreciated that the work we do and the documentation we provide are correct and on time. Our goal is to exceed our customers expectations. Do it right and do it right the first time.

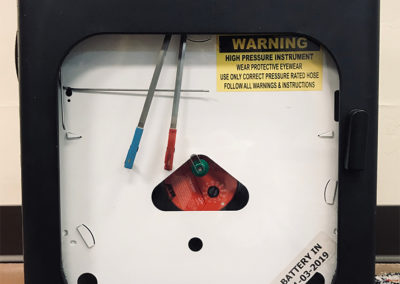

Pressure calibrations are performed in our lab using the newest Fluke technology. The Fluke Electronic Deadweight tester is ideal for calibrating high-pressure gages and transducers. Many of our customers require calibrations of their pressure gages and transducers with high levels of accuracy. With the Fluke electronic deadweight tester, we can accurately test pressure up to 30,000 psi. An accurate standard is very important when doing this type of calibration. Many manufacturing processes require pressure measuring done very accurately. With our Fluke pressure source, we can ensure proper operation and accurate pressure readings. Check us out for your pressure calibrations.

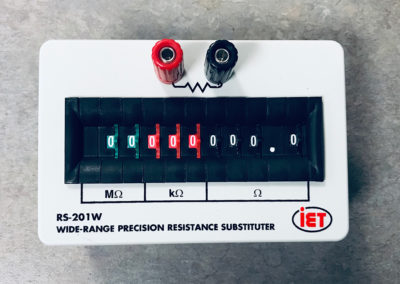

A calibration lab requires many things to operate correctly. There are many different types of calibration standards used to test the huge variety of test and measurement equipment. Precision Calibrations is determined to meet or exceed our customer needs by continually monitoring and deciding what equipment should be updated or upgraded. It is important for us, as a calibration lab, to continually seek out better equipment and monitor the new processes available for calibrations. You can rest assured that your calibration will be done accurately and timely each time you visit us. We look forward to visiting with you next time you stop in.

Each calibration is done very carefully without prejudice to brand, make or model. Each item that comes into our lab is treated with the utmost care. Customers sometimes drop off their items to our lab in Claremore Oklahoma and others hand deliver to our location. Each item is inspected for damage and the lab technician allows the item to sit and acclimate to the lab environment for enough time to ensure proper measurements at a given temperature. Our lab is maintained at 70 degrees plus or minus 2 degrees. If it is important to our customer to have proper reading tools it is important to us to ensure the best calibration possible.

Precision Calibrations is family owned and operated. The Founder, Nathan Saylor, has opened his business up to his family and as a result, gets to enjoy life as grandpa while on the job. Our team is small but mighty. Built on the backs of both men and women, young and aged. Our levels of education pertinent to calibrations varies but our mindset remains the same – Customer satisfaction is priority. We work day and night to ensure that every customer is more than satisfied with our service and would feel comfortable referring us to a friend. Our google reviews are a perfect example of the quality of our service.

Many of our customers are in the aerospace industry. It is very common to see parts being manufactured that will require being dried in an oven or heat treated. Precision Calibrations offers a service to ensure that an oven is running properly throughout the entire work zone. A technician will hang a certain number of thermocouples throughout the work zone that will plug into a digital chart recorder. The chart recorder will log all the data for the duration of the survey and will allow us to generate a formal report reflecting the given temperatures during the test. This fulfills the customers requirement to verify the oven function and gives them a very informative idea of the condition of their oven.